E-Type Rail Clip, also known as E-type elastic rail clip, is a widely used railway fastening component designed to securely fix rails to sleepers or base plates. It provides stable clamping force, absorbs vibration, and maintains rail position under dynamic train loads.

E-type rail clips are commonly applied in railway track construction, metro systems, and heavy-haul railways, and are compatible with various railway fastening systems.

To ensure reliable performance and long service life, E-type rail clips are manufactured through a strictly controlled production process.

High-quality spring steel is selected, such as:

60Si2Mn

55SiCr

Other equivalent alloy spring steels

All raw materials are inspected for chemical composition and mechanical properties before production.

Steel bars are heated and formed into E-type shape using automatic hot forming and bending equipment, which ensures:

Accurate geometry

Uniform internal structure

Stable elastic properties

Heat treatment is a key process to achieve optimal elasticity and strength:

Quenching and tempering

Controlled hardness and elastic recovery

This ensures the rail clip maintains long-term clamping force under repeated train loads.

Different surface treatments are available to improve corrosion resistance:

Hot-dip galvanizing

Mechanical galvanizing

Black oxide finish

Surface treatment helps extend service life in outdoor and corrosive environments.

Each batch of E-type rail clips undergoes:

Dimensional inspection

Elastic force testing

Fatigue and surface quality checks

Only qualified products are released for delivery.

E-type rail clips provide reliable mechanical performance in railway fastening applications:

High elastic clamping force for secure rail fixation

Excellent fatigue resistance for long-term use

Strong vibration damping, reducing rail movement

Stable gauge maintenance under heavy axle loads

Good corrosion resistance in various climates

These features make E-type rail clips suitable for both conventional and heavy-duty railway systems.

Railway fastening systems

Concrete sleeper track

Heavy-haul railway lines

Metro and urban rail transit

Railway track maintenance and renewal

Based on international railway projects and export experience, customers usually focus on the following points:

Stable and uniform clamping force is critical for railway safety. Our E-type rail clips are tested to ensure consistent elasticity.

E-type rail clips can be manufactured according to drawings, samples, or specific railway standards, ensuring full compatibility.

High fatigue resistance and corrosion protection help reduce maintenance frequency and operating costs.

Strict inspection procedures ensure dimensional accuracy and mechanical reliability for every batch.

Mass production capability supports large-volume orders and long-term project supply.

Professional railway fastener manufacturer

Advanced production and testing equipment

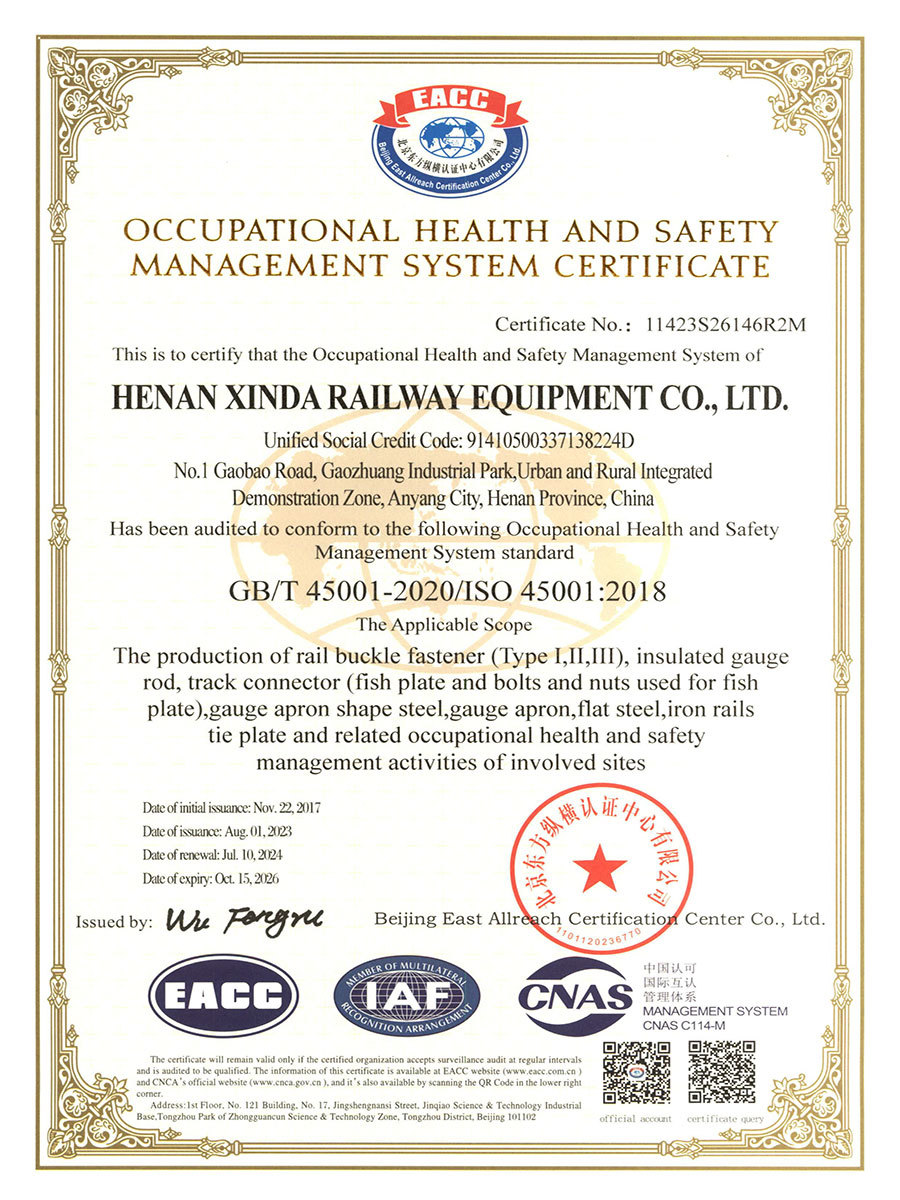

Strict quality management system

Competitive factory-direct pricing

Rich export experience

OEM and ODM services are available to meet different project requirements.

Henan Xinda Railway Equipment Co., Ltd. is located at No. 1, Gaobao Road, Gaozhuang Industrial Park, Urban-rural Integration Demonstration Zone, Anyang City, Henan Province. The company covers an area of 200 acres and has nearly 400 employees, including 56 technical R&D personnel. The company is committed to the goal and vision of "accelerating to become the world's number one brand of rail fastening accessories". It adheres to technology-based and service-first principles , has established a leading position in the industry.

Strong independent innovation capabilities

The company has been engaged in the production and research and development of rail buckle accessories for 30 years. It has obtained more than 30 patents and has become the first inventor of disruptive innovation in the heating system of elastic strip production lines in the same industry in China. The new metal heat treatment products quenching fluid and passivation fluid jointly developed by the company and university scientific research units have various technical indicators superior to foreign imported products, completely surpassing similar foreign products, greatly reducing customers' use costs, creating ultimate value for customers, and filling the domestic gap. The company has successively won the honorary titles of national "high-tech enterprise", "Gazelle" enterprise in Henan Province, the only "Enterprise Technology Center" in Anyang City, Henan Province, and "Specialized, Advanced and Innovative" enterprise in Henan Province. It has taken the lead in building the only "Postdoctoral Innovation Practice Base" in Anyang City in Henan Province.

Strict "four best" target management system

Extremely high standards: The company is committed to building a strict quality control system, cultivating the quality awareness of all employees, and continuously optimizing the extremely high standards and mechanisms of product design, promoting industrial upgrading, product upgrades, and service upgrades.

Minimalist actions: The company is committed to streamlining business processes, optimizing production processes, and promoting a simple culture. It has established a seamless connection mechanism from research and development to testing to application, which has greatly improved the efficiency of the transformation and application of scientific research results.

Extremely fast: The company is committed to establishing a rapid response decision-making mechanism for product development and production, quality control and logistics delivery, etc., which has improved the efficiency of production services, fully cooperates in strengthening team communication, and strives to meet user needs.

The results have been great: The company is committed to creating the ultimate value for users, from once to a lifetime; it is committed to promoting organizational restructuring and service transformation, and strengthening the expansion of market channels; it is committed to building a competitive organization throughout the industry chain to create the ultimate value for users.

Product quality standard of “hundred years of stainless products”

The company has two factories, equipped with 6 automatic and digital production lines for rail clips. It has new technologies and equipment for metal surface penetration, plating, spraying and coating, which can make the surface of rail accessories rust-free for 100 years. Products are divided into two categories: non-metal parts and metal parts. Non-metal parts include high-speed rail height-adjusting pads, rubber pads, nylon baffles, nylon casings, and polymer nylon rubber and plastics, etc.; metal parts include gauge baffles, special pad steel for turnouts, type I. The products are widely used in rail laying projects of high-speed railways, normal-speed railways and urban rail transit.

User-centered pursuit of win-win cooperation

Based on the changes in customer needs, the company uses a safe and fast low-cost logistics system and promises that delivery from the user's order to the designated location will take no more than 48 hours (to be determined through negotiation in remote areas). Behind this commitment is the company's efficient response decision-making mechanism, optimized production process and close team communication and collaboration to ensure efficient services for users. At present, the railway paving provided by the "Raisling" brand rail fastener products can circle the earth, and has achieved "zero accidents, zero delays, and zero complaints."The company's newly developed steel products and clip quenching fluid and passivation fluid products have been sold in the railway, electromechanical, chemical and other industries. As the saying goes, "Forging tough bones, tempering the compression-resistant character, the greenness recedes, the clips dare not call themselves gold and steel." The new products have become the company's new growth engine. At present, the company's single product market share ranks first, and it is the undisputed leading brand in the industry.

The company will continue to adhere to its development positioning of "technology-led and user-centered", keep up with the "One Belt,One Road" construction needs of domestic and foreign railway development, "stand on high ground, adhere to the right path and innovate", continuously improve product quality and service level, provide customers with more cost-effective, excellent and valuable products, and contribute to the high-quality development of the global railway industry.