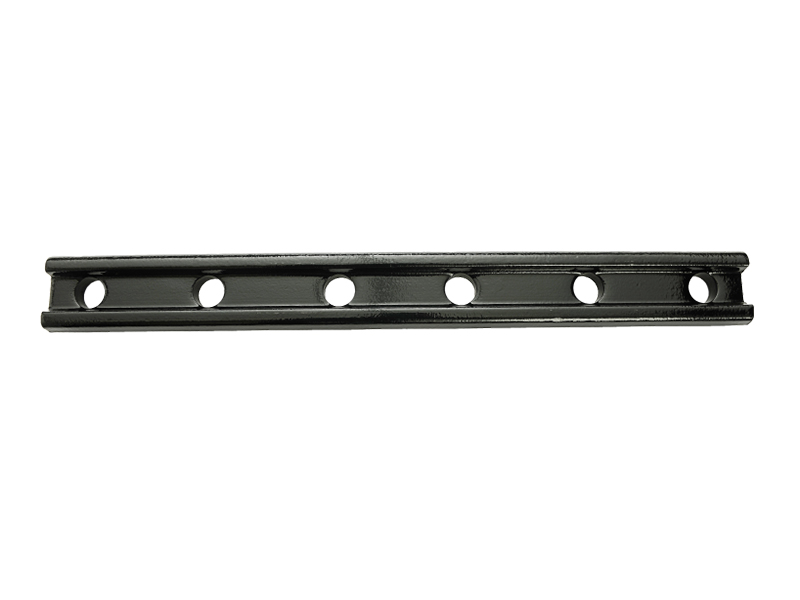

P65 Fishplate

P65 Fishplate – Reliable Rail Joint Bar for Track ConnectionThe P65 fishplate, also known as a P65 rail joint bar, is a vital component used to connect adjacent rail sections in railway track systems. It is designed for use with P65 rails, providing a robust connection that ensures accurate rail alignment, mechanical stability, and efficient load transfer. P65 fishplates are essential in mainline railways, heavy-haul lines, and industrial rail networks, where performance and durability are critical.Production Process of P65 FishplateThe production of P65 fishplates involves several critical steps to ensure high-quality and precision:Material Selection: The fishplate is typically made from high-strength carbon steel, selected for its excellent mechanical properties, which provide the required strength and durability.Forging and Machining: The steel is heated and forged into the basic shape of the fishplate. Once cooled, it is precisely machined to ensure correct dimensions and a perfect fit for the rail profile.Surface Treatment: The fishplates are subjected to surface treatments such as galvanization, black oxide, or other corrosion-resistant coatings to enhance their durability, especially when exposed to harsh environmental conditions.Quality Control: Each P65 fishplate undergoes strict dimensional and mechanical testing to ensure it meets both international standards (UIC, DIN, BS) and the customer’s specific requirements. These quality checks ensure that the fishplates perform optimally in various railway track conditions.Performance of P65 FishplateThe P65 fishplate provides several key benefits that are essential for railway track systems:High Mechanical Strength: The fishplate is made from high-strength steel, ensuring the rail joint remains stable under heavy axle loads and dynamic forces from passing trains.Vibration Absorption: P65 fishplates help to absorb and distribute the vibrations generated by the moving trains, thus reducing stress on the rail and prolonging the lifespan of both the track and the rail.Corrosion Resistance: With proper surface treatment, such as galvanization or black oxide, P65 fishplates can withstand exposure to weather, moisture, and other corrosive elements, making them ideal for use in various climates.Long Service Life: Designed for durability, P65 fishplates ensure stable rail alignment and minimize track maintenance, resulting in reduced downtime and repair costs over time.Easy Installation and Maintenance: The design of the P65 fishplate allows for quick installation and easy maintenance, providing convenience for railway operators and reducing labor costs.Why Choose Our P65 Fishplates?When it comes to P65 fishplates, choosing the right supplier is crucial for the long-term performance of your track system. Here’s why customers trust our products:High-Quality Manufacturing: Our P65 fishplates are manufactured to the highest standards, ensuring they meet rigorous international specifications such as UIC, DIN, and BS.Customized Solutions: We offer customization options to meet your specific project requirements, including customized dimensions and surface treatments.Competitive Pricing: As a direct manufacturer, we provide highly competitive pricing for bulk orders, making our fishplates an affordable solution for large-scale railway projects.Efficient Delivery: We ensure fast and reliable delivery, with a well-established logistics network for international shipments, reducing lead time for customers.Strong After-Sales Support: Our experienced customer service team is available to support you with technical questions, installation guidelines, and after-sales assistance.Applications of P65 FishplatesThe P65 fishplate is suitable for use in:Mainline railway systemsHeavy-haul freight railwaysIndustrial railwaysMetro and urban rail transitTrack maintenance projectsIt provides a stable and durable solution for connecting P65 rail sections, maintaining track geometry, and ensuring the safety and stability of railway operations.Packaging & DeliveryPackaging: P65 fishplates are securely packed in standard export wooden pallets or steel pallets, ensuring safe delivery to international destinations.Delivery: We offer fast, reliable shipping options worldwide, ensuring that your order arrives on time and in excellent condition.Contact UsIf you are looking for a high-quality P65 fishplate manufacturer or supplier, please contact us for technical drawings, samples, or competitive quotations. Our team is ready to provide you with the best solution for your railway track projects.We also supply other rail joint bars, including P50, P60, and P75 fishplates.